SUPPRESSOR DEVICES FOR RELAY COILS

The inductive nature of relay coils allows them to create magnetic forces which are converted to mechanical movements to operate contact systems. When voltage is applied to a coil, the resulting current generates a magnetic flux, creating mechanical work. Upon deenergizing the coil, the collapasing magnetic field induces a reverse voltage (also known as back EMF) which tends to maintain current flow in the coil. The induced voltage level mainly depends on the duration of the deenergization. The faster the switch-off, the higher the induced voltage.

All coil suppression networks are based on a reduction of speed of current decay. This reduction may also slow down the opening of contacts, adversly effecting contact life and reliability. Therefore, it is very important to have a clear understanding of these phenomena when designing a coil suppression circuitry.

Typical coil characteristics

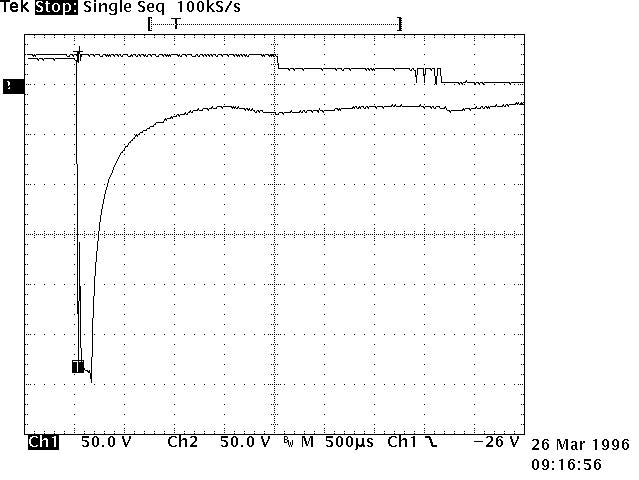

On the graph below, the upper record shows the contacts state. (High level NO contacts closed, low level NC contacts closed, intermediate state contact transfer). The lower record shows the voltage across the coil when the current is switched off by another relay contact.

The surge voltage is limited to -300V by the arc generated across contact poles. Discharge duration is about 200

mircoseconds after which the current change does not generate sufficient voltage. The voltage decreases to the point where the contacts start to move, at this time, the voltage increases due to the energy contained in the NO contact springs. The voltage decreases again during transfer, and increases once more when the magnetic circuit is closed on permanent magnet.

Operating times are as follows:

Time to start the movement 1.5ms

Total motion time 2.3ms

Transfer time 1.4ms

Contact State

Types of suppressors:

Passive devices.

The resistor capacitor circuit

It eliminates the power dissipation problem, as well as fast voltage rises. With a proper match between coil and resistor, approximate capacitance value can be calculated from:

C = 0.02xT/R, where

T = operating time in milliseconds

R = coil resistance in kiloOhms

C = capacitance in microFarads

The series resistor must be between 0.5 and 1 times the coil resistance. Special consideration must be taken for the

capacitor inrush current in the case of a low resistance coil.

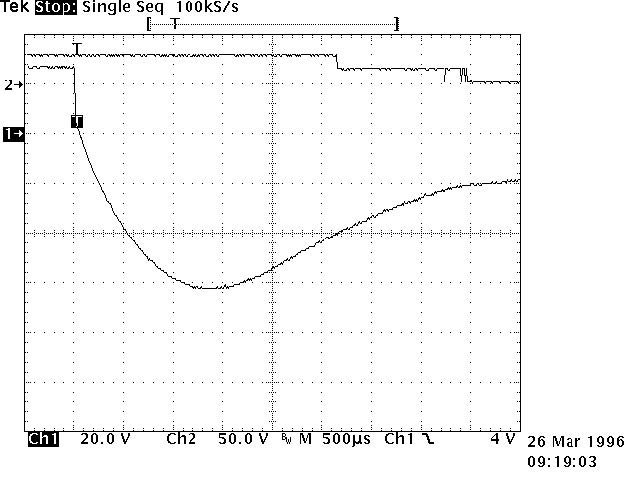

The record shown opposite is performed on the same relay as above. The operation time becomes:

– time to start the movement 2.3ms

– transfer time 1.2ms

The major difficulty comes from the capacitor volume. In our example of a relay with a 290 W coil and time delay of 8 ms, a capacitance value of C=0.5 uF is found. This non polarized capacitor, with a voltage of 63V minimum, has a volume of about 1cm3. For 150V, this volume becomes 1.5 cm3.

The bifilar coil

The principle is to wind on the magnetic circuit of the main coil a second coil shorted on itself. By a proper adaptation of the internal resistance of this second coil it is possible to find an acceptable equilibrium between surge voltage and reduction of the opening speed. To be efficient at fast voltage changes, the coupling of two coils must be perfect. This implies embedded windings. The volume occupied by the second coil reduces the efficiency of the main coil and results in higher coil power consumption. This method cannot be applied efficiently to products not specifically designed for this purpose.

The resistor (parallel with the coil)

For efficient action, the resistor must be of the same order of magnitude as the coil resistance. A resistor 1.5 times the coil resistance will limit the surge to 1.5 times the supply voltage. Release time and opening speed are moderately affected. The major problem is the extra power dissipated.

Semi-conductor devices

The diode

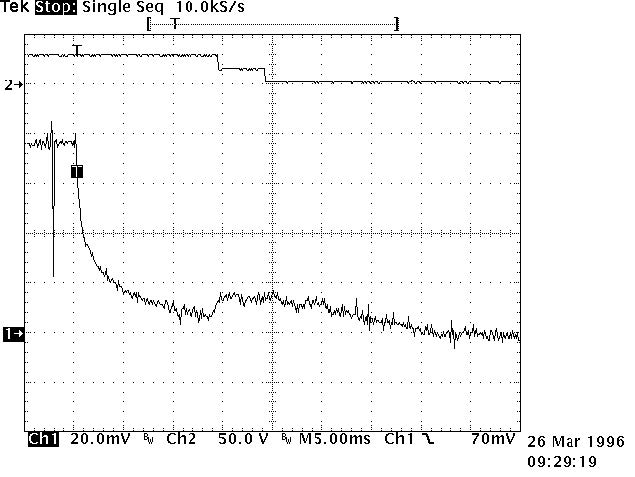

It is the most simple method to totally suppress the surge voltage. It has the major disadvantage of the higher reduction of contact opening speed. This is due to the total recycling, through the diode, of the energy contained in the coil itself. The following measurement is performed once again on the same relay. Operation times are given by the upper curve:

– time to start the movement 14ms

– transfer time 5ms

These times are multiplied by a coefficient from 4 to 8.

The lower curve shows the coil current. The increase prior to NO contact opening indicates that the contact spring dissipates its energy. At the opening time the current becomes constant as a result of practically zero opening speed.

Due to this kind of behavior, this type of suppression must be avoided for power relays. For small relays which have to switch low currents of less than 0.2 A, degradation of life is not that significant and the method may be acceptable.

The diode + resistor network

It eliminates the inconvenience of the resistor alone, explained above, and it limits the action of a single diode. It is now preferred to used the diode + zener network.

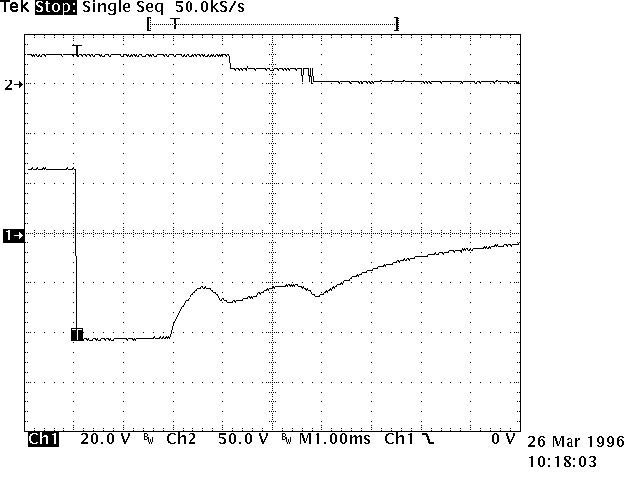

The diode + zener network

Like the resistor, the zener allows a faster decurrent decay. In addition it introduces a threshold level for current conduction which avoids the recycling of energy released during contact movement.

The lower curve on the opposite record demonstrates those characteristics. Voltage limitation occurs at 42V. The two voltages spikes generated by internal movement are at lower levels than zener conduction. As a result, no current is recycled in the coil.

The opening time phases are as follows:

– time to start the movement 2.6ms

– total motion time 2.4ms

– transfer time 1.4ms

The release time is slightly increased. The contacts’ opening speed remains unchanged.