Facilities

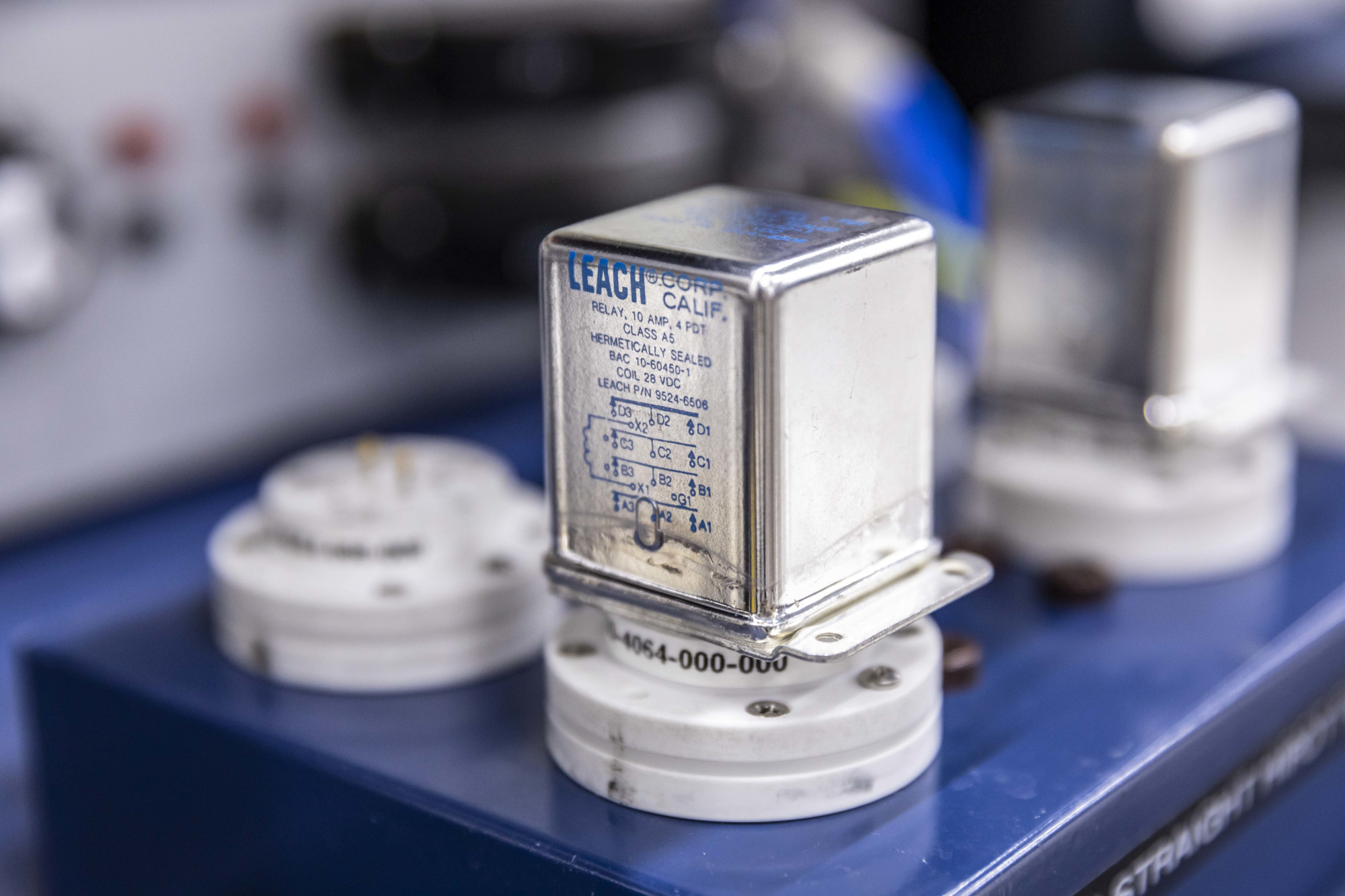

Between our two locations, the combined square footage comes to 190,000 square feet, fully equipped with the cutting-edge technology and expertise to make Leach an industry expert. We rely on our leading electrical switchgear, distribution, and circuit protection to deliver top electrical service to our customers.

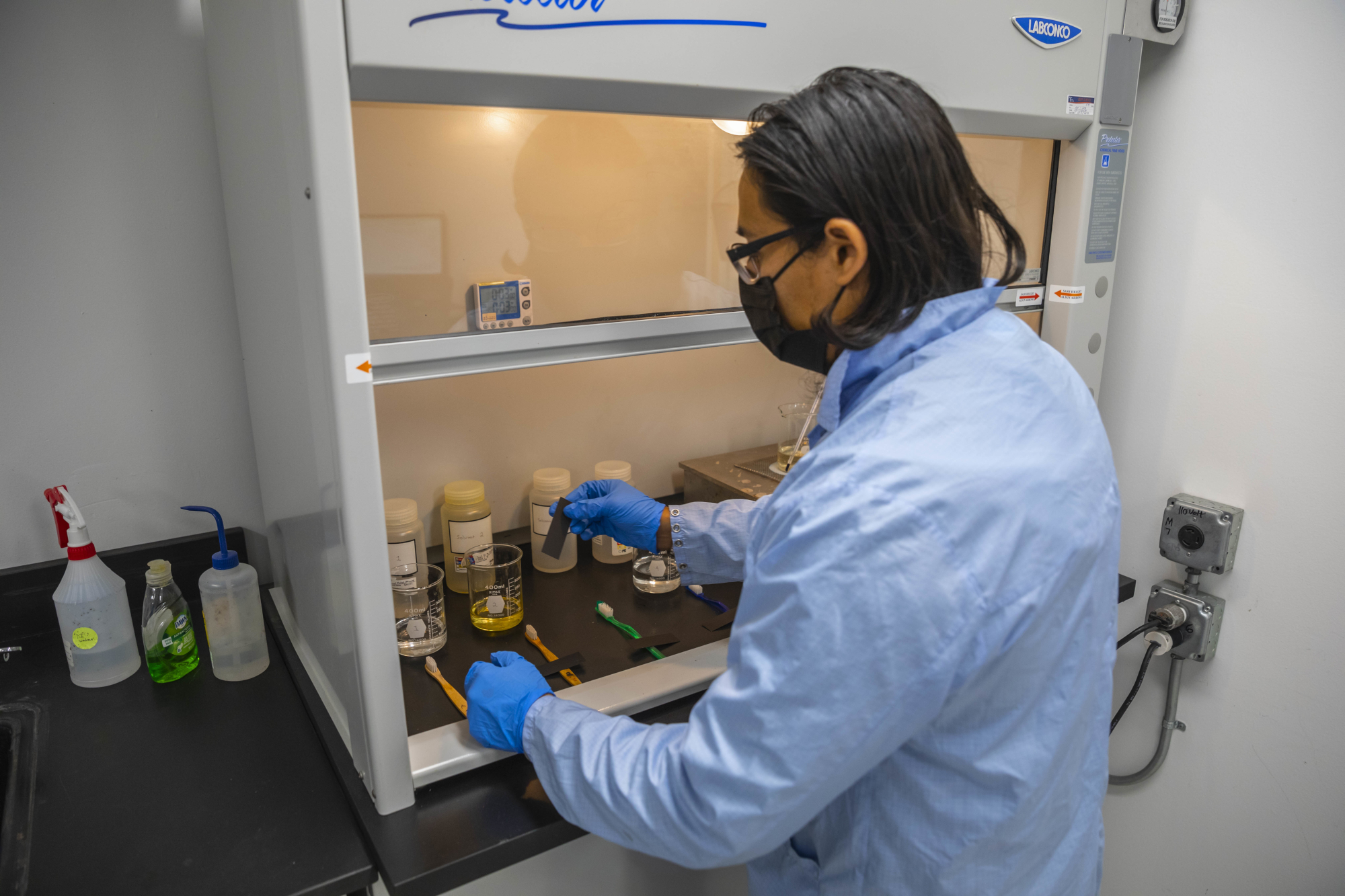

The Leach International Corporation headquarters is a state-of-the-art facility located in Buena Park, California, housing engineering, research & development, and all support functions. The facility has operated in this location since 1994. Final assembly and testing is completed in Buena Park; meanwhile, a large percentage of our subassemblies are manufactured in Leach’s Tijuana facility which opened in 1980. The Tijuana facility not only provides cost competitive manufacturing it also houses a wide range of complex manufacturing processes. Everything from sub assembly to annealing, plating, coil winding, soldering and welding. Between Buena Park and our Mexico operations, Leach is able to complete several dozen of the most complex processes required to produce all of your power distribution needs.

Our diverse and state-of-the-art facilities allow us to stay vertically integrated and control our own supply chain. By keeping multiple levels of production within our own organization, we avoid overdependence on third-party suppliers. This level of vertical integration allows us better control over our development and production programs.

Our facilities are transforming and evolving under Leach’s new leadership as we invest in ourselves as a company. In order to provide exceptional service and prioritize our clients, we have already begun a series of upgrades, automations, and updated systems and equipment.

TESTING & QUALIFICATION

Our reenergized focus is on creating an environment that yields success — achievements that shine throughout our facilities.

Our reenergized focus is on creating an environment that yields success, and these achievements have already begun to shine within and around our facilities.

Having in-house test capabilities which meet and exceed Mil-spec standards, our team can design, develop and test components which range up to 4000 amps at 28VDC and up to 1000 amps at 270VDC. For AC loads, our teams can develop and test components and systems which when paralleled, can meet 2700 amps per phase at 115VAC @ 400Hz.

To meet temperature requirements, we can use in house equipment for a range from -70˚C to +140˚C. To meet the high mechanical reliability targets, our vibration and shock testing capabilities include a computer controlled random vibration table of 3300 force pounds and up to 2000 G’s of shock. In addition, our altitude chamber has capability of up to 80,000 ft. from -70˚C to +125˚C. This is a very small snapshot of our testing and qualification capabilities and our fully staffed and equipped qualification laboratory is capable of designing any type of load or current profile with built in circuit protection to meet or exceed reliability goals.

Over the course of a century, the Leach name has become synonymous with “reliability” and “high-quality performance.” As we continue to contribute to industries where performance is flight-critical, we are inherently proud of our commitment to quality.

Under new leadership, we are investing in ourselves as a company to provide our customers with exceptional service. Over the next few years, you’ll see a transformation at LEACH, from new technology and systems to different policies and internal management systems. This evolution will be gradual and intentional, focusing on creating an environment that yields industry leading performance.

We are coming together as a team to ensure growth, evolution, and innovation.