Building Quality Control at Leach

Nini Ayon

Nini Ayon

Manufacturing Engineering Director

Understanding Vertically Integrated Manufacturing

In manufacturing, vertical integration means taking control of multiple stages of the production chain rather than relying entirely on external suppliers. It’s a strategy that requires significant investment and expertise, but for companies operating in demanding industries like aerospace, it can be the difference between meeting critical deadlines and explaining delays to frustrated customers. At Leach, we’ve built our manufacturing approach around this principle, controlling key processes from component fabrication to final product.

While many manufacturers focus on finding the most cost-effective suppliers, we made a different calculation: controlling quality and delivery times is worth the complexity of managing multiple manufacturing processes in-house. In the aerospace industry, component failure is potentially catastrophic, not to mention expensive, so our vertically integrated approach allows us to maintain the stringent quality standards needed while delivering products on time, even when global supply chains face disruption.

The Payoff

Our facilities are designed to support vertical integration, enabling us to oversee everything from piece parts manufacturing and sub-assemblies to final assembly and shipping. Our Tijuana facility alone houses over 500 pieces of specialized equipment and 20 production lines, covering processes such as metal stamping, annealing, plating, coil winding, soldering, and welding. This streamlines communication, reduces errors, and accelerates production timelines. The specific benefits we’ve realized include:

Consistent product quality through direct oversight at each stage of manufacturing, ensuring products consistently meet stringent industry standards

Reduced lead times and costs by minimizing dependence on external suppliers and quickly adapting to changes in customer demand

Supply chain stability providing greater resilience against disruptions and allowing for rapid response to market or customer needs

Cost management by consolidating production processes, achieving economies of scale, and reducing per-unit production costs

Enhanced customer service through our ability to quickly adjust production and maintain high standards, resulting in reliable, on-time delivery

Operational efficiency supported by continuous improvement, automation, and lean manufacturing methodologies

All of this plays a role in reducing the lead time of manufacturing – we can act quicker to produce faster, at a lower cost, while managing the quality we build into each part.

Continuous Improvement Through Investment and Listening

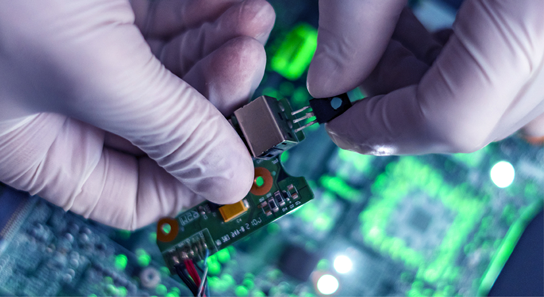

We take steps to continually improve our manufacturing processes every year by investing back into our company and our employees. For example, we’ve invested in Surface Mount Technology pick-and-place systems, which automatically position electronic components onto circuit boards with high precision and speed. We also use Automated Optical Inspection equipment, which uses cameras to automatically inspect assemblies for defects and placement errors. And we’re continuing to expand our automation in test and manufacturing processes at both our Buena Park, California, and Tijuana, Mexico sites.

Quality and consistency across all stages of production come from working as a team cross functionally, standardizing our manufacturing and inspection processes, and using our subject matter experts in building our in-house capabilities, skills, and talent. Crucially, this involves listening to our employees, who know the manufacturing and testing processes best. We work with their ideas to continually improve.

We Take the Long View

While vertical integration requires sizable upfront financial outlays, in the right circumstances, the strategy serves to streamline the process of manufacturing to the delivery of a product. The aerospace industry presents unique challenges that make this investment worthwhile. When you’re manufacturing components for aircraft systems, there’s little room for the variability that comes from juggling multiple external relationships, and great benefit in building the deep expertise that comes from owning the process. For us, vertical integration is how we ensure that the components we deliver today will perform reliably for decades to come.

Nini Ayon

Manufacturing Engineering Director

Nini Ayon, Manufacturing Engineering Director at Leach Corp, brings an 18-year track record in engineering, notably with L3Harris. Her UC San Diego education and APICS certifications underpin her expertise in power distribution systems.

Celebrated for her Six Sigma success and team development, Nini is also an awarded community leader and avid

volleyball player.