Skylab: Meeting the Demands of a More Electric Aerospace Industry

Sanaz Sheybani

Sanaz Sheybani

Sales and Application Engineer,

Leach International Corporation

In the rapidly evolving aerospace industry, the transition towards More Electric Aircraft (MEA) is driving a need to develop higher-power products. The MEA market is experiencing robust growth driven by increasing demand for energy-efficient aircraft, rising air travel, heightened environmental awareness, and technological advancements in electrical systems. The aerospace sector has responded over the last decade with significant advancements in onboard power systems. This shift – replacing traditional mechanical, hydraulic, and pneumatic functions with electric systems – has brought numerous benefits, including cost reductions and the ability to design and configure systems in various ways to meet specific requirements.

However, with these advancements come stringent regulations and a heightened focus on safety and reliability. Challenges in developing electric aircraft and connectivity systems include managing significantly higher voltages and power, mitigating the partial discharge/corona effect at altitude, ensuring increased reliability in harsh environments, prioritizing weight reduction, resisting arc tracking and hydraulic fluids, adhering to strict flammability, toxicity, and smoke requirements, and addressing altitude and pressure effects.

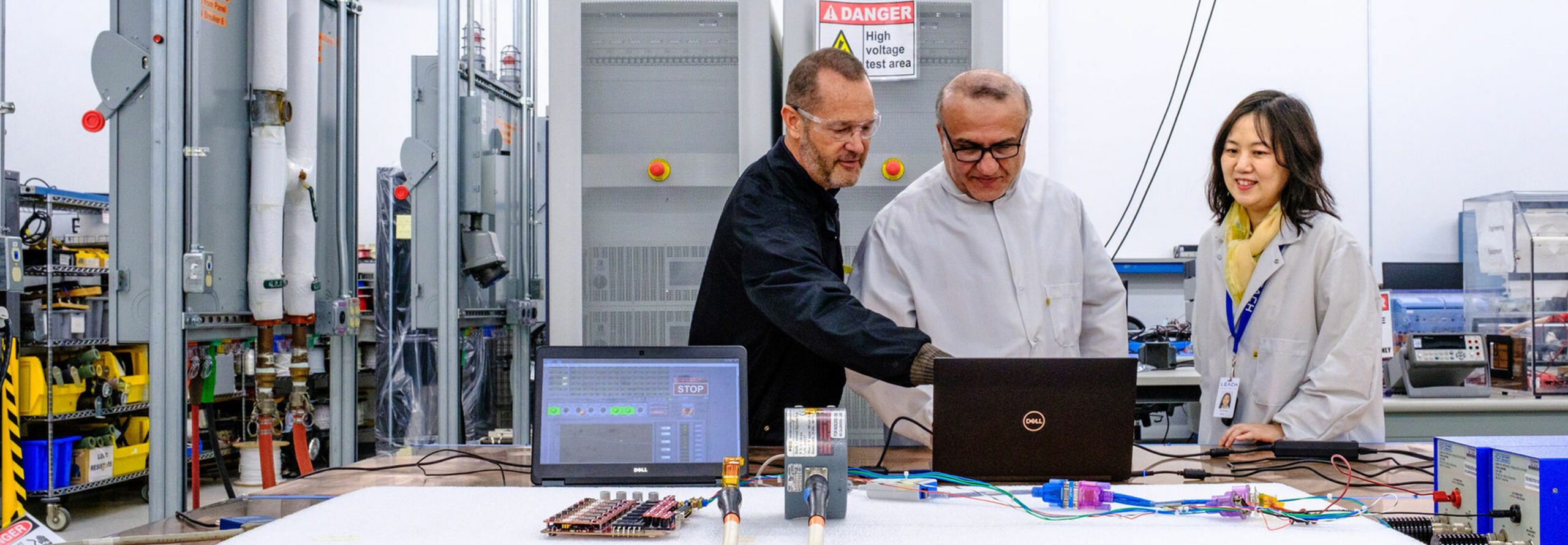

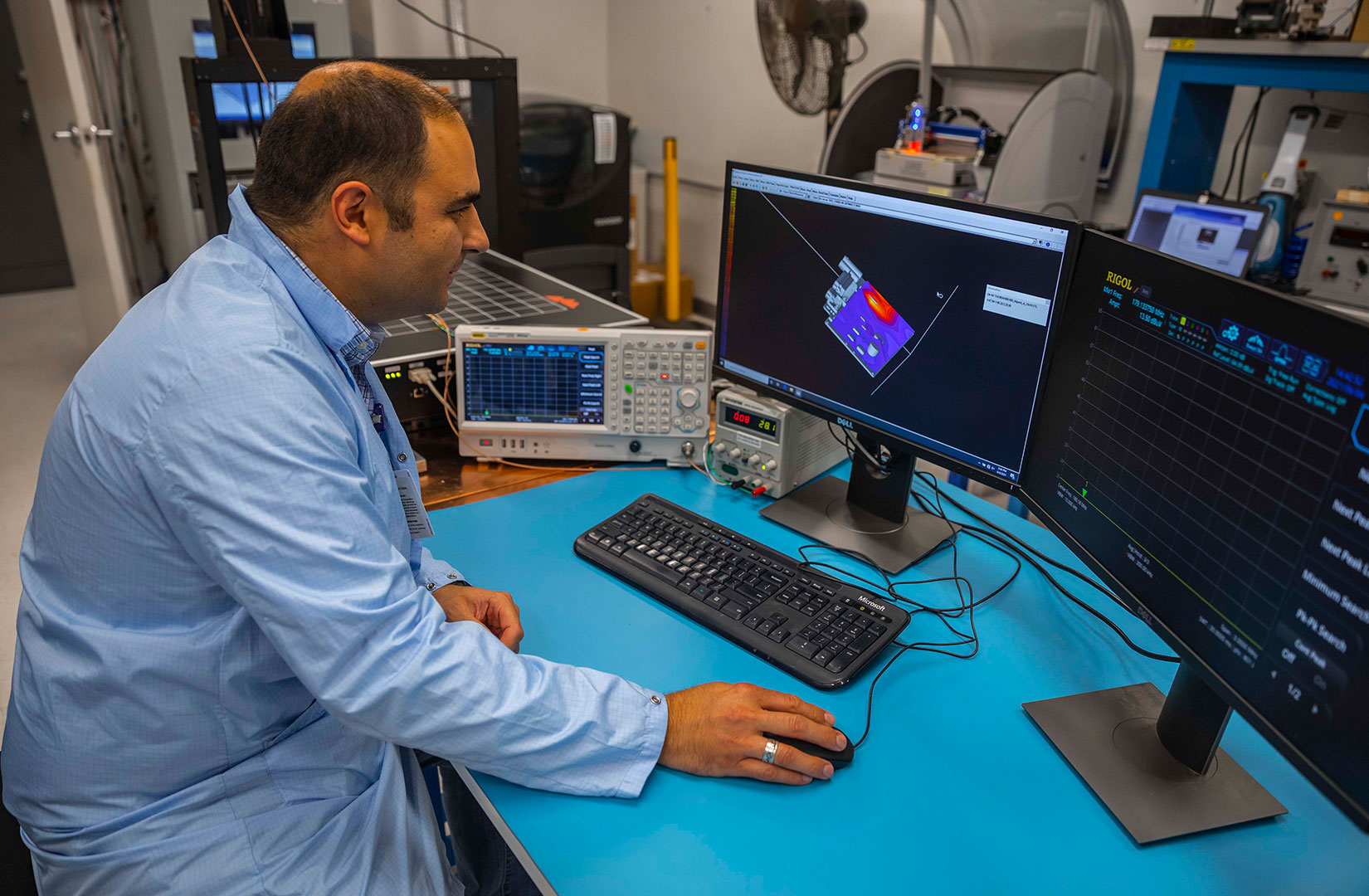

Leach’s laboratory, Skylab, with its advanced testing and development capabilities, is built to address these challenges, providing comprehensive testing to ensure the efficiency, safety, and reliability of electric aircraft systems. It is a sophisticated environment for designing, testing, validating, and certifying the new generation of complex electrical systems.

The Skylab edge: Spearheading aerospace electrical testing

Comprehensive testing must address different aspects of component behavior under various conditions, essential for validating reuse of component. Crucially, it also guides the extensive research and development that go into a range of Leach’s new products. Leach’s Skylab is a state-of-the-art testing facility at the forefront of addressing these evolving needs in the aerospace industry.

The facility, with its unmatched high-voltage power capacity, boasts one of the highest capacities in the US. It is specifically designed for the development and testing of electrical systems in the next generation of more electric aircraft (MEA), encompassing commercial, military, space, electric Vertical Take-Off and Landing (eVTOL), and business aviation sectors.

Capabilities

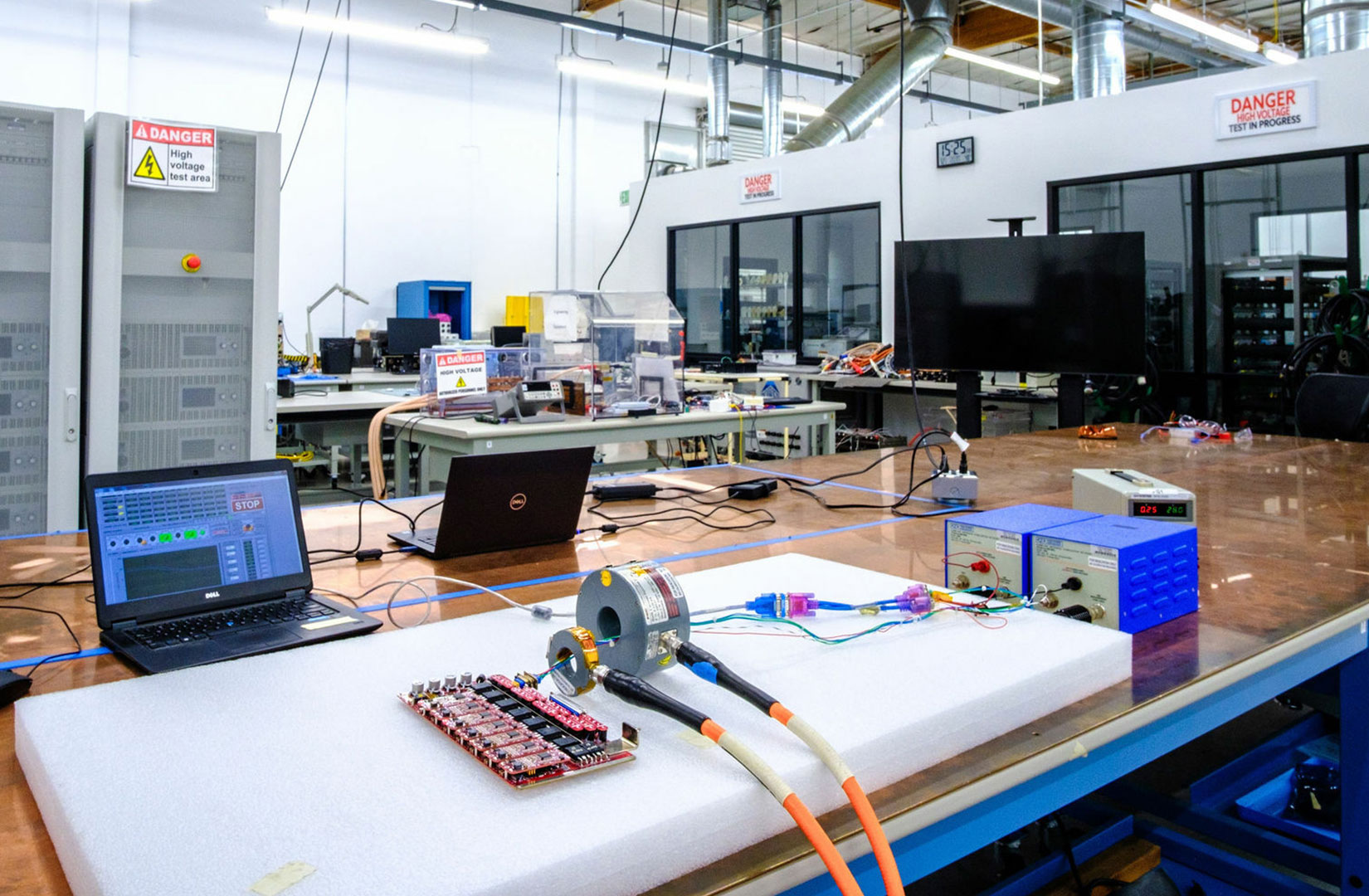

The array of Skylab’s test equipment ranges from high-voltage power supplies to various load banks and environmental stress screening tools. The 4200 sq. ft. testing space allows for safe high-voltage testing and efficient heat dissipation, essential for high-power testing. Key features include:

- High-power testing: The facility can test high power up to 1 MW, crucial for validating the performance and safety of electrical components under extreme conditions.

- Variety of testing levels: It can test AC and DC levels up to 1 MW VDC. The range of high AC and DC level testing includes from 115/208 VAC at 400 Hz & VF to 220/440 VAC at 400 Hz & VF, as well as various DC levels like 270 VDC at 1 MW, 540 VDC at 250 KW, and 1000 VDC at 400 KW.

- EMI preliminary testing for conductive susceptibility, and Electric Field Scanner capabilities to ensure the electromagnetic compatibility of components.

“The aerospace industry has a continuing expectation for increased electrical power demand with More Electric Aircraft (MEA) for both flight-critical and mission-critical applications. Leach has recognized our customer’s electrical requirements, and we have invested in very high-power test lab capability as part of our impressive electrical power distribution pedigree and new product introduction.”

-Darin Friess, Vice President of Engineering at Leach Corp

Testing, testing, testing …

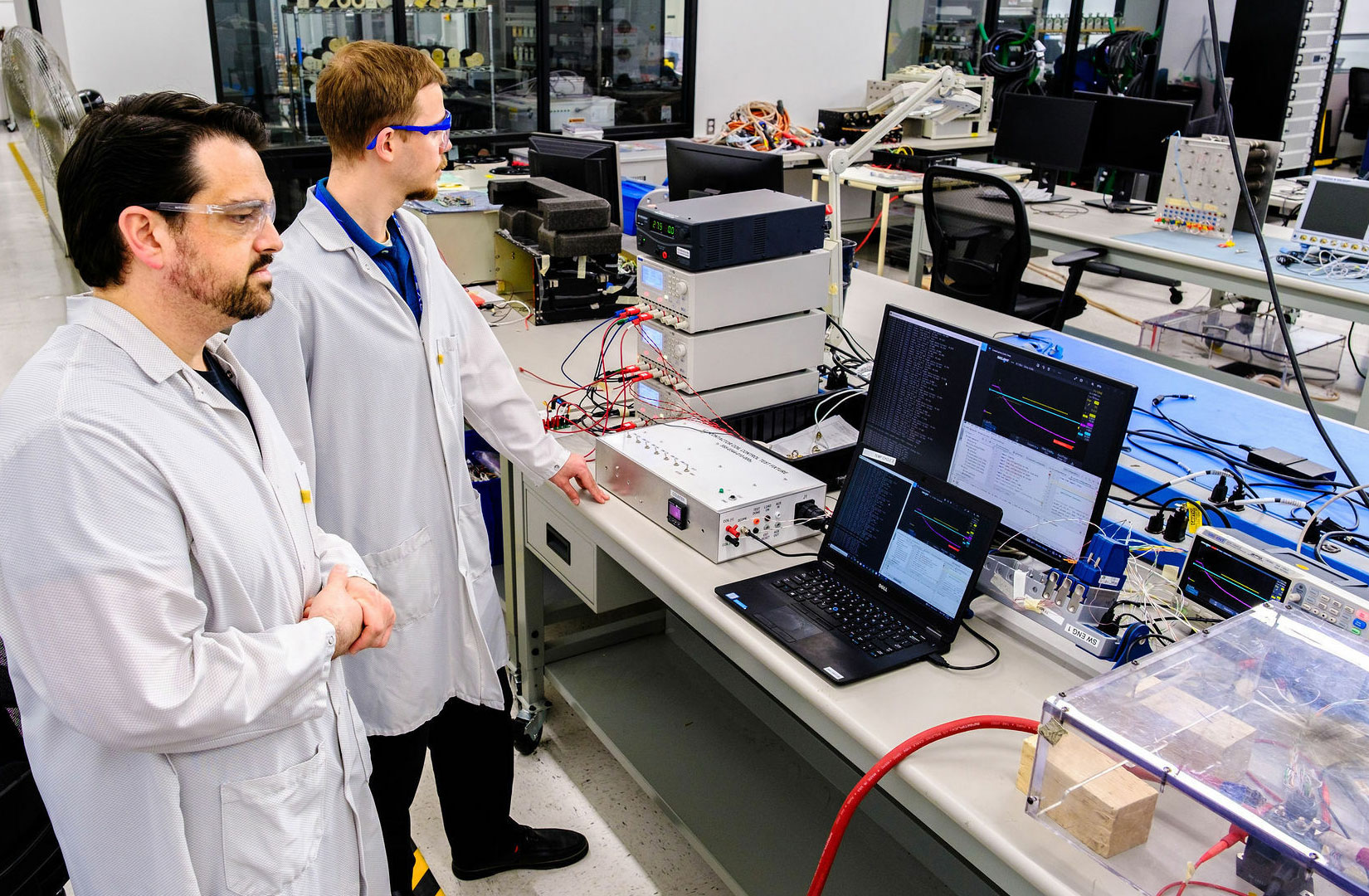

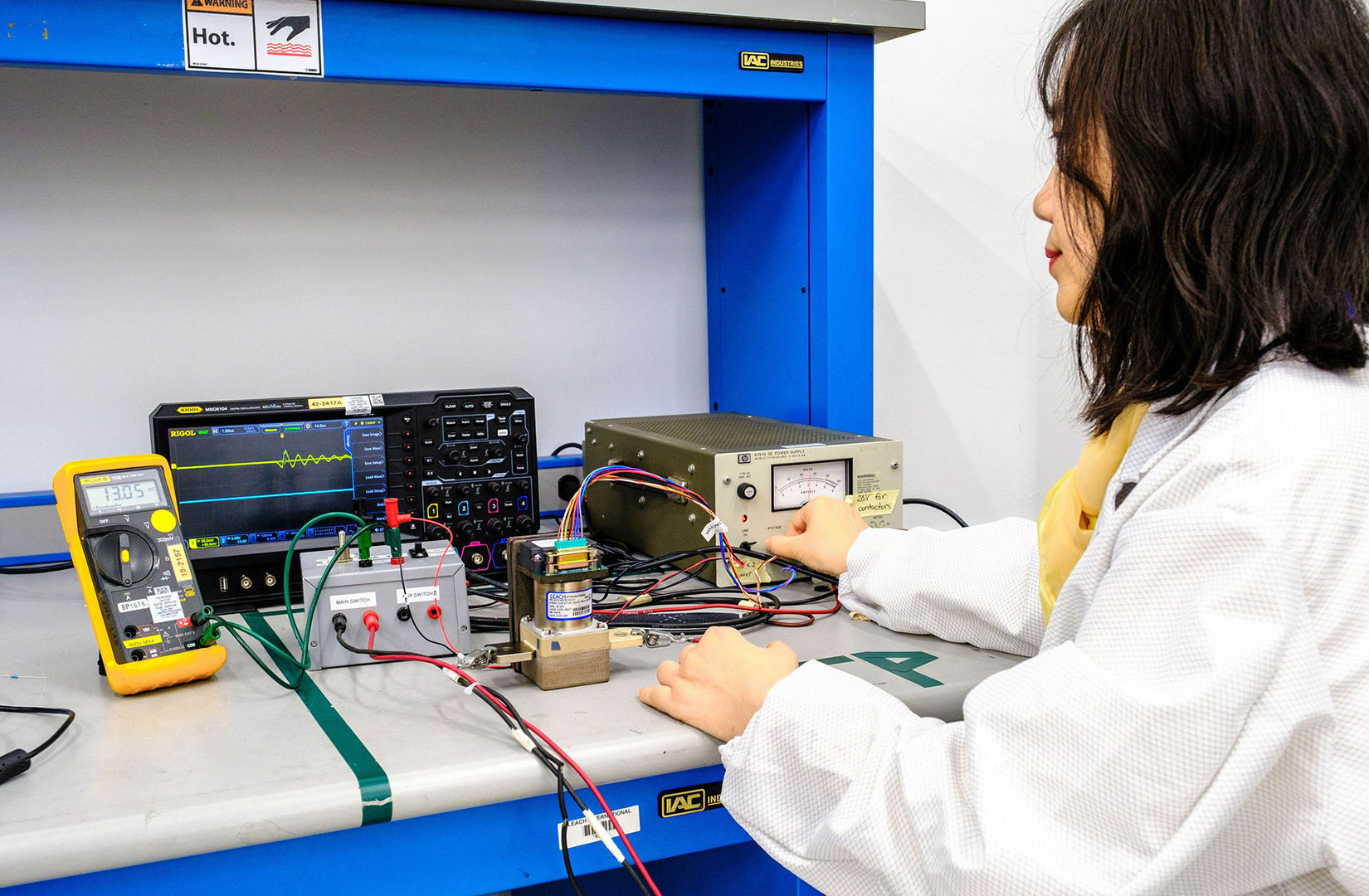

Skylab’s array of equipment allows Leach to test and analyze a wide range of conditions that aerospace products may encounter. High-voltage power supplies give us the ability to test products up to 1000 V. Load banks, including resistive, inductive, capacitive, and programmable types, allow us to assess how products perform under different electrical loads.

High-voltage testing tools, such as probes, scopes, and chart recorders, ensure precise measurement and recording of electrical properties. For altitude testing, our altitude chamber simulates conditions up to 70,000 feet. Our temperature chamber handles extreme ranges, from -55°C to 150°C, simulating extreme environmental aircraft conditions.

Specialized equipment for vibration and shock testing allows us to test products against a range of possibilities for movement and impact, and our thermal shock chamber tests products’ resilience against sudden changes in temperature.

Leach uses Environmental Stress Screening (ESS) and Highly Accelerated Life Test (HALT) methods. ESS enables us to identify potential product weaknesses by exposing them to various environmental stresses, while HALT pushes products to their operational limits, ensuring that they meet the highest standards of reliability and durability.

–

Leach expanded Skylab to meet the demands of a significant and prestigious program we were awarded. Now, we can work on larger-scale projects, accommodating more extensive setups and test equipment, including the high-power requirements needed for testing advanced products. If you are interested in rigorous testing and verification for next-generation aircraft systems and power distribution equipment with high efficiency and optimized package size, please contact us at: Relayed@leachcorp.com

–

Sanaz Sheybani

Sales and Application Engineer at Leach International Corporation

With a Master of Science in Electrical Engineering and certifications in project management, marketing, and operations, Sanaz brings expertise to Leach Corp. Fluent in English, French, and Persian, she excels in global communication. Previously, Sanaz led projects developing anti-icing windshield heaters for light commercial jets. Outside work, she enjoys travel, skiing, scuba diving, culinary adventures, and dancing.