The Evolution of Solid State Power Control: From Transistors to Jets

Kyle Cantu

Kyle Cantu

Engineering Innovator,

Leach International Corporation

SSPCs – How did we get here?

The origins of Solid State Power Controllers (SSPCs) can be traced back to the post-WW2 development of semiconductor and solid-state electronics technologies, heralded by the invention of the transistor in 1947. Transistors offered a smaller, more reliable, and energy-efficient alternative to the vacuum tubes and electromechanical switches used previously. In the late 1950s, thyristors (a blend of ‘thyratron’ and ‘transistor’) were a crucial component in the development of SSPCs. Thyratron was an earlier gas-filled tube device used for electronic switching, and the invention of the thyristor represented a significant advancement in the ability to control large currents using semiconductor materials.

Thyristors paved the way for the creation of SSPCs by providing a reliable, solid-state method for controlling power distribution. Initially, they were primarily silicon-based, but advancements included the development of silicon carbide (SiC) thyristors, which can operate at higher temperatures and offer improved performance in demanding environments. The stage was set for all subsequent advancements in semiconductor devices, including SSPCs.

The transition to solid-state solutions was driven by the need for more precise control, increased safety, improved reliability, and enhanced diagnostic capabilities in aerospace applications as well as the swift escalation of complexity in aircraft electronic systems. Particularly on military platforms, this posed significant challenges for effectively managing electrical power distribution, load management, status monitoring, safety, and reliability. Traditional power distribution methods, reliant on discrete electromechanical devices, struggled to accommodate the increasing complexity and meet the stringent requirements for size and weight. These challenges are further compounded by the need for advanced power management strategies, including load shedding, redundancy, and power sequencing.

SSPCs at work: High-voltage power management

Higher voltages and the need for more efficient power management brought new challenges. Engaging and disengaging electrical circuits under load (hot-switching) causes wear and tear from arcing and mechanical stress. This is particularly acute in More Electric Aircraft (MEA) and High Voltage Direct Current (HVDC) systems where higher voltages and currents raise concerns around durability and reliability. HVDC systems, which conduct electrical power using direct current, are increasingly used in aircraft for their efficiency and reliability over long distances.

SSPCs overcome the challenges of hot-switching, due to their solid-state nature. This attribute alone significantly extends the lifespan of power distribution components. They offer full solid-state power switch capabilities along with sophisticated monitoring and communication features. The integration of an overcurrent trip curve shields wiring and loads from excessive current draw or short circuits – a critical safeguard against system anomalies. Through their soft-switching characteristics, high reliability, fast response time, and ability to facilitate advanced load management, SSPCs are becoming an accepted alternative to electromechanical contactors and circuit breakers.

SSPCs represent the next wave in circuit protection technology, safeguarding wiring and facilitating the management of loads from afar. By substituting several electromechanical components with a singular electronic board, SSPCs streamline power systems and significantly reduce the complexity and weight of wiring. Thanks to their electronic capabilities, SSPCs can be enhanced with additional features such as logic command-based actuation, arc-fault detection, current monitoring, and the ability to relay data directly to crew members or maintenance systems.

The breakthrough implications of SSPC technology lie in their precise control over power distribution, ensuring higher operational efficiency and safety. Their solid-state nature allows for seamless integration into various systems, providing real-time monitoring, protection against overcurrent conditions, and remote configuration capabilities. This level of control and diagnostics introduces a previously unattainable level of flexibility and adaptability in power distribution systems.

Hybrid contactors – pragmatic reliability

The patented 270 VDC, 1,000 Amp Leach Hybrid Contactor design offers a pragmatic approach to power switching, effectively bridging traditional electromechanical contactors and solid-state technologies. This design significantly increases hot-switching life and reliability, while maintaining galvanic isolation. Hybrid contactors offer the low on-resistance characteristic of electromechanical systems alongside the advanced non-arcing power-switching capabilities inherent to solid-state devices. This integration serves to enhance the hot-switching lifespan and reliability for applications where these attributes are paramount.

The durability and reliability of electromechanical systems, attributed to their galvanic isolation, remain unmatched in certain scenarios. This makes hybrid contactors especially useful for applications that demand high-current capabilities or are deemed mission-critical. They are used where the transition to SSPCs is not likely and where galvanic isolation is critical.

Advancements in SWaP – compact, lightweight efficiency

SSPCs make a significant contribution to the aerospace industry’s efforts to improve energy efficiency and reduce environmental impact. The drive for Size, Weight, and Power (SWaP) reductions in SSPC design underscores the continuous push for innovation in the aerospace industry. Through the miniaturization of components, the utilization of advanced materials, and improvements in thermal management, Leach engineers have successfully reduced the physical footprint and weight of SSPCs while enhancing their power-handling capabilities.

SSPCs have evolved significantly from their early implementations. The advancements in semiconductor materials, microelectronics, and digital control technologies have led to SSPCs that are more compact, efficient, and capable of handling higher voltages and currents. This evolution reflects the broader trends in power electronics and solid-state technology, moving from bulky, less efficient systems to highly integrated, high-performance solutions.

Compact, flexible SSPCs from Leach

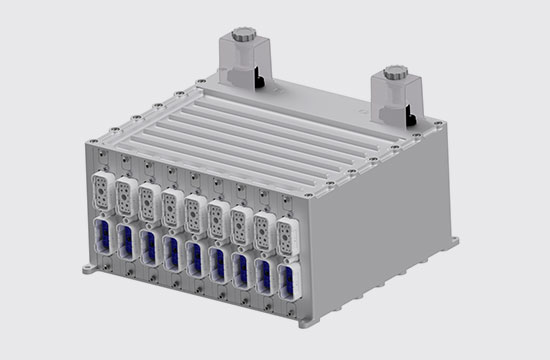

Leach International Corporation’s SSPCs are a leap forward in aerospace power management, capable of handling the complex requirements of modern aerospace vehicles, from commercial airliners to advanced military applications. They offer substantial savings in weight and volume thanks to their highly integrated design.

Our portfolio includes versatile power-switching devices for AC and DC systems, equipped with advanced current sensing for comprehensive protection. Designed as Line Replaceable Units for easy maintenance and featuring modular concepts for future reconfiguration, Leach Corp’s SSPCs embody both flexibility and efficiency.

Contact one of our engineers here to learn more.

Kyle Cantu – Engineering Innovator

Engineering Lead, RPDA Business Unit, Leach International Corporation

With 8 years in the field, Kyle Cantu has made significant contributions as the Engineering Lead of the RPDA Business Unit. Graduating from The Ohio State University with a specialization in Power and Signal Processing, Kyle’s expertise includes high-voltage solid-state switches and integrated design solutions. Kyle is distinguished by holding a patent in high-voltage switchgear technology, reflecting his contribution to Leach’s product line.