Understanding Reliability Engineering: MCBF and MTBF

Dan Parker

Dan Parker

Reliability, Maintainability, Safety and

Component Engineer

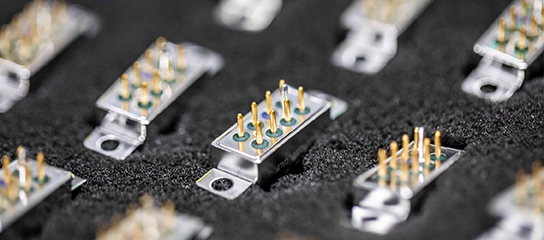

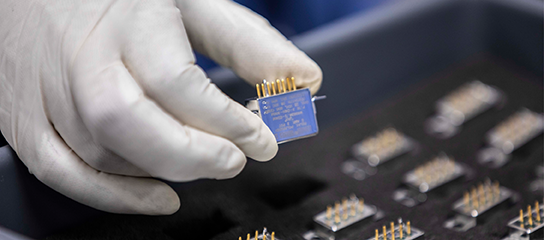

Reliability engineering predicts and manages component failures, including Leach International components used in critical aerospace applications. These components carry a predicted statistical rate of failure, measured in failures per million hours, and a maximum operational cycles measurement. The accuracy of any reliability prediction depends on proper component selection based on the operational environment. Factors such as temperature, vibration, circuit stress levels, and component construction quality all influence failure rates.

Predicting when components will fail is essential for safety, maintenance planning, and calculating operational costs. Two reliability metrics guide this understanding: Mean Time Between Failure (MTBF) and Mean Cycles Between Failure (MCBF). MTBF guides design decisions and component selection, whilst MCBF validates real-world operational performance.

MTBF provides statistical predictions during the design phase based on component stress analysis and environmental factors, typically measured in failures per million hours. This metric helps engineers select and derate components during the design phase, ensuring reliable performance in the intended operating environment.

MCBF measures how many operational cycles a component can actually withstand at its full rated specifications. Rather than statistical modeling, MCBF relies on qualification testing to provide concrete performance data.

For Leach, both metrics play crucial, distinct roles in delivering the exceptional reliability that power distribution components demand. During product development, MTBF serves as the primary reliability verification tool. It validates that component selections align with environmental requirements and stress levels. This statistical foundation allows engineers to model various scenarios and optimize designs before physical testing begins. MTBF’s strength is in its predictive capability when proper derating guidelines are followed. This early-stage analysis prevents costly redesigns and field failures.

How MTBF Works

Mean Time Between Failure (MTBF) is a statistical measurement based on the total summation of subassembly failure rates. The methodology relies on stress analysis and component derating guidelines, typically following established frameworks like the Reliability Engineer’s Toolkit, and ensuring components operate well within their specified limits.

Component Derating

A critical factor determining prediction accuracy is proper component derating. Derating ensures the component operates well within a proven margin of its capabilities, protecting against environmental variations, manufacturing tolerances, and unexpected transients. This practice limits electrical, thermal, and mechanical stresses to levels below the manufacturer’s specified maximum ratings during the design phase.

Structured guidelines are used to determine exact stress limits for each component type, and a scoring system that considers reliability challenges, system repair requirements, safety factors, size constraints, and lifecycle costs. Engineers aim for derating scores mandated for specific stress and temperature limitations for different component types. For example, a derating guideline may dictate that a film resistor must operate at no more than 50% of its rated power and at least 40°C below its maximum temperature limit. The score grades a design’s risk level based on three factors:

Reliability: How proven or novel the design is.

System repair: How difficult or costly it is to repair the system.

Safety: The potential consequences of a failure.

The methodology remains the most widely used approach for reliability modeling during product development phases.

Dry Switching Myth

An important aspect of selecting the right components for the operating environment is understanding the minimum ratings, as well as the maximum.

A common misconception is that dry switching – operating a contactor or relay with a very low current – is always the most reliable option for high-current applications. This is not true. Contacts often require a minimum amount of current to break through surface films and establish a stable, low-resistance connection. Without this ‘wetting’ current, contact resistance can build up over time, leading to excessive heat generation, intermittent operation, and even failure, especially in sealed or potted terminals where heat dissipation is limited.

Naturally, this impacts predicted reliability, so simply configuring a contact to be ‘dry’ isn’t a safe strategy. To avoid these failure modes, consult the manufacturer’s specifications for the minimum load current, just as you would for derating. This ensures the chosen component can meet the performance and longevity predicted by its MTBF and MCBF ratings.

Dry switching combined with high-current carry does not prevent mechanical wear or the thermal effects of prolonged high-current flow, both of which can overheat contact materials and the entire device. Because this combination also prevents contacts from reaching their optimum current carrying condition, dry switching is not recommended.

During normal use, contact voltage drop (CVD) decreases as surfaces develop electrical conditioning through repeated switching under load. This conditioning improves conductivity and reduces heating. Rated CVD values represent worst-case limits; actual CVD in conditioned contacts typically runs well below Product Control Drawing specifications. Pristine contacts lack this conditioning. Fresh, smooth surfaces are less efficient at conducting high currents than conditioned ones, resulting in greater surface heating and increased tack welding risk at rated current limits. The contacts become more susceptible to welding during overload or rupture events because there is less effective conductive surface area. Dry switching designs that carry high currents across unconditioned contact surfaces should be approached with caution due to their unique weld-related failure mechanisms.

Putting Theory to

the Test

Leach’s H-A3A-002 helicopter contactor project provides evidence of MTBF accuracy when proper derating is applied. We shipped 4,969 units to a helicopter manufacturer and analyzed returns. The data revealed that most returns stemmed from non-reliability issues: missing documentation, customer-induced damage, installation problems, and no-fault-found scenarios. When we filtered those out, we found only two true, random hardware failures over an estimated 2.5 million hours of field usage. This yielded an actual field failure rate of 0.805 failures per million hours.

We then built a reliability prediction model using standard military handbook methods (MIL-HDBK-217), inputting the exact environmental conditions, electrical stress (17% of the contactor’s rating), and cycle rate. The model predicted a failure rate of 0.808 – a near-perfect match to the real-world data (0.805).

This case proves that when you derate components properly and understand the operational environment, MTBF is an accurate and powerful tool for predicting reliability.

The Value of

MTBF Modeling

During the development phase, reliability engineering verifies that selected components suit both the application and the operating environment. The process involves analyzing temperature ranges, platform types (for example, aircraft vs helicopter), quality construction standards, and form factors. These inputs collectively determine the MTBF calculation.

MTBF modeling is also valuable for production planning and field support operations. It helps with accurate spare parts provisioning. Customers can anticipate when failures might occur and plan maintenance schedules accordingly.

The Role of MCBF

While MTBF predicts time-based reliability, many components like relays and contactors are also rated by their electrical and mechanical endurance, or Mean Cycles Between Failure (MCBF). An MCBF rating is a qualification-based expectation. If we claim 50,000 cycles on the Product Control Drawing (PCD), we test and confirm that this can be met during the development cycle. Qualification is always done on production pedigree hardware.

Leach’s approach to MCBF is defined by the fact that we test our products at their maximum rated current and voltage for the full duration of the claimed cycle count. If we say a contactor is rated for 50,000 cycles at 800 V and a specific current, that is exactly what we test it at. This is a key differentiator, as many other manufacturers will only guarantee a high cycle count (e.g., 10,000 cycles) at a significantly reduced current, providing a derating curve for higher loads. This comparative analysis using 100 aircraft as a baseline illustrates this advantage:

With four contactors per platform and typical flight hour requirements, Leach’s 50,000-cycle rating translates to approximately 5 failures per year across the fleet.

Competitive products rated at 10,000 cycles would experience roughly 27 failures annually – more than a five-fold increase in maintenance requirements.

While competitors rely on derating curves and reduced specifications at higher loads, Leach maintains full performance ratings throughout the specified operational envelope.

Once products enter service, MCBF provides concrete performance expectations based on actual testing data. For applications with well-defined cycling requirements, it offers direct operational guidance without statistical interpretation and eliminates uncertainty about performance under specific conditions. When one of Leach’s contactors carries a 50,000-cycle MCBF rating at full specifications, operators know exactly what performance to expect throughout the operational envelope.

Other Engineering Considerations

Switching

Make-carry-break – This is the normal operational use for a primary power contactor, operating at or below rated current and voltage. It also includes operation at overload and rupture current levels. All Leach products are qualified under this operational condition.

Hot make-cold break – When exposed to high inrush, overload, or rupture current levels, this condition frequently leads to tack welding and should be avoided, particularly if contacts have not been conditioned through make-carry-break operation. Devices used in this fashion require special designs, materials, and design considerations. Their rated lifespans and reliability typically differ from conventional contactors.

Dry switching – This is switching with no current or voltage supplied, providing only galvanic isolation. However, the contactor remains vulnerable to tack welding if exposed to high current levels and higher than necessary CVD due to low contact conditioning.

Continuous

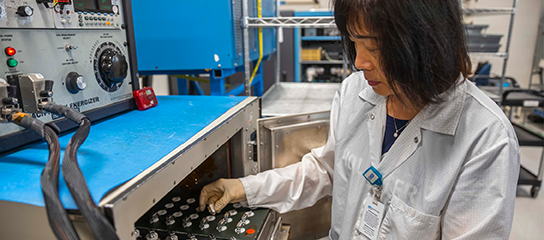

current

Leach performs continuous current testing at full rated current and voltage, specified altitude (typically 30,000 to 70,000 feet), and temperature (71°C or 85°C ambient). The soak time is 100 hours at rated load and environment before all operability parameters are measured. This ensures the device meets worst-case, long term operating conditions and that its temperature does not pose a hazard to other equipment.

Mechanical life

Leach typically tests at 25% of rated current and room ambient temperature. The device must meet the minimum specified

mechanical cycles, typically 100,000. However, this is not the limit of mechanical durability. Leach products commonly achieve 150% to 300% of their rated requirement due to design parameters that drive higher-than-required reliability.

Electrical life test

Testing is typically conducted with rated resistive load requirements at full rated current and voltage. Half of the life test

is done at elevated temperature, the other half at room ambient. Test duration is typically 50,000 cycles. As with mechanical life, the rated cycle count is not the limit. Products commonly achieve 150% to 300% of their rated requirement due to design parameters that drive higher reliability. Since most switches operate below rated currents, their lifespans are even longer.

Tests using inductive, motor, overload, or rupture loads show similar behavior, far exceeding required ratings. While overall life is shorter due to demanding load profiles, the extended life percentages remain consistent.

Long periods of non-operation can cause contacts exposed to atmosphere to oxidize, resulting in high CVD and increased likelihood of tack welding.

MTBF and MCBF are Complementary

MTBF and MCBF are complementary pillars of reliability – both help predict maintenance requirements and failure patterns. MTBF is a powerful, accurate prediction tool for time-based failure when the operational environment is known and components are properly derated during development. It remains the most widely used method for modeling reliability and planning for spare parts and logistics.

MCBF, on the other hand, is a performance-based rating grounded in physical testing. It proves the mechanical durability and switching endurance of a product, providing a clear, comparable metric that directly impacts operational efficiency and cost. Together, they provide a complete picture of a product’s capability and reliability.

Dan Parker

Reliability, Maintainability, Safety and Component Engineer

Dan Parker is the Reliability, Maintainability, Safety and Component Engineer with over 20 years of experience in the civil and defense aerospace sectors. He has worked on several development programs, including the P-8A Poseidon and the E-7 Airborne Early Warning and Control (AEW&C) Wedgetail, Peace Eagle and Peace Eye. At Leach, he is responsible for electronic component derating and circuit stress analysis, reliability predictions, maintainability and safety analyses of Solid State Power Controllers (SSPCs) and Power Distribution Assemblies (PDAs). He has assisted the Design Team with electronic component selection for use in all subassemblies. In addition to these activities, he is the primary component engineer who works with Supply Chain to ensure components are readily available to sustain the product line for years to come. He holds a Bachelor of Science in Electrical Engineering from Purdue University.

Dan is an avid grilling enthusiast, enjoys spending time with family and relaxing in Sedona, Arizona, during holidays.